What's New in Kitchen iQ - 4.36

22 April 2025

click here for past feature updates

Technical

Kitchen iQ Routing after POS account saved

Routing Rules in Kitchen iQ are now re-calculated after an account is saved on the Aztec POS, ensuring that any late changes to an order are routed correctly. This calculation occurs automatically in the background after selecting Save on the till and no configuration is required. The changes support sites that make adjustments to an order after items are already added, such as changing the table number. Kitchen iQ will then route orders based on the orders conditions set prior to selecting save on the Aztec POS.

Improvements have been made to the Channels Customer View Split Screen, released in Kitchen iQ 4.35. Front end changes were implemented to prevent orders overlapping on certain screens and to ensure text appears centred in each section. Sites that want to use this Customer View should take this latest release.

Detailed Updates

Find the latest detailed updates across Kitchen iQ

Past Feature Updates

Configuration & Onsite Operations

Channels Customer View enhancements

Additional Configuration settings for Channels Customer View have been introduced. This includes an option to split screen for ready and preparing orders, option to increase order cell size and option to change order cell colour displayed on site screens. These changes will improve accessibility and customers can easily to identify orders at collection areas. For more information click here.

Configuration & Onsite Operations

Channel limit increase

The Site's Configuration Channel limit has been increased from 25 to 50, allowing large and growing sites to setup specific Channels to display on each screen and improve the visibility of orders in each area.

Configuration & Onsite Operations

Station Dish Allocation with Routing Rule filters

Routing Rules can now be configured to allow Station Dish Allocation be applied with any additional filters. This was previously restricted and now allows sites to configure more specific Routing for each order.

Technical

Dragontail integration - promise times

Promise Times fields and other unused fields that the Dragontail Integration do not utilise will be ignored and not passed in the call made from Kitchen iQ.

Technical

Dragontail integration - external order ID

The external order ID will be mapped from Kitchen iQ to Dragontail, supporting order fulfilment and delivery through external providers including Uber Marketplace.

Technical

Optimisation for Site Server

Technical changes to the Kitchen iQ Site Server code have been implemented to improve performance and stability of the application, while maintaining existing functionality. These changes are particularly important to support busy customer sites.

Technical

Optimisation for Site Server Database

Technical changes to the Kitchen iQ Site Server database have been implemented to improve performance. Note: database upgrade was not included in this release as previously outlined. Further updates to the progress of this upgrade will be available in the next release.

Configuration & Onsite Operations

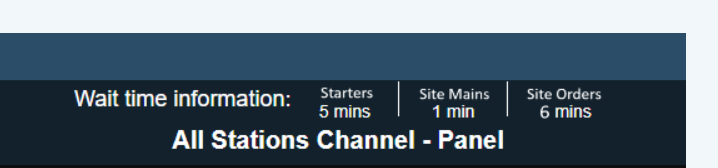

Wait Times

Automatically calculate an estimated wait time for an order to be ready.

Multiple calculations can be configured to determine Wait Times on specific courses and terminal group areas on a site.

Results can be displayed on site in the Channels screen, allowing front of house staff to understand and communicate how long the order should take to complete. This feature increases customer satisfaction, keeps them informed and reduces the uncertainty of Wait Times.

For more information click here

Onsite Operations - Average Times

Site Server - Average Times Export

When Average Times is configured in Channel settings, a JSON file will now be exported to the install path of the Kitchen iQ site server PC. This file will be overwritten each minute with all information on the Average Times configuration and the actual times calculated. Users will have the ability to access and use this data externally if needed.

-

Select Channels | Enable Average Times

-

Set either Prep or Delivery to be shown in the Average Time drop down

-

Ensure that the channel is configured for a screen in Site | Kitchen Screen | Allowable Channels

Onsite Operations

Tag Child Order Lines in Non Actionable Tickets

An enhancement to the 'Tag Child Order Lines' feature introduced in 4.31 now allows tags to be applied even to non-actionable items. For example, an order may still be in the preparation or assembly stage, but a serving channel operator can still tag items as needed.

Other Features & Information

| Feature | Description |

|---|---|

| Automate Install: Audit Extractor |

During the install for Audit Extractor, the IP Address will now be requested from the machine and auto-populated. The install process for sites out on the field can be a time consuming manual process. This enhancement will help automate part of the installation process for Audit Extractor, which will make the task more efficient and lower the risk of error. |

Configuration & Onsite Operations

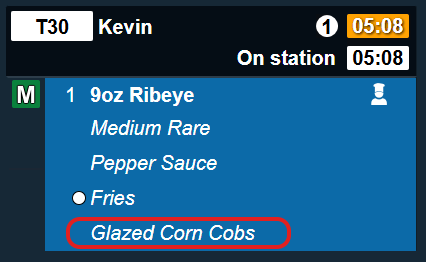

Tag Child Order Lines

To improve operations it is now possible to "tag" child order line items.

When a channel is set to 'Panel View' with child lines configured as 'One Per Row,' an onsite operator can navigate between child lines using the bump bar's item up / down buttons. A red selection outline will highlight the chosen item. Pressing the 'Bump' button tags the item, displaying a white circle next to it. To untag an item, simply repeat the process. Tagged items are visible across all channels viewing the ticket.

Child items are those linked to a main (parent) item. For example, a steak is the parent item, while sauces, sides, and cooking temperature are its child items.

Visually identifying child items that have been prepared or served helps maintain awareness of order status.

Tagging items does not affect the normal process of bumping the main item.

Configuration & Onsite Operations

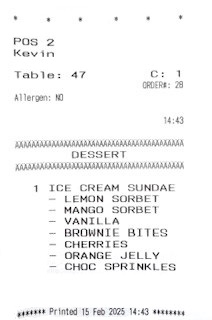

Print & Display Bumped Items Only

In service scenarios where items are served to guest as soon as they are ready, a new print rule ensures that active items are printed, with the option to print only the individual item when necessary.

-

Select Printing | add a new rule Any Item is Active

-

Select the check box Print Item Only, this will print each individual item as it becomes in the active, for example at the ready order stage

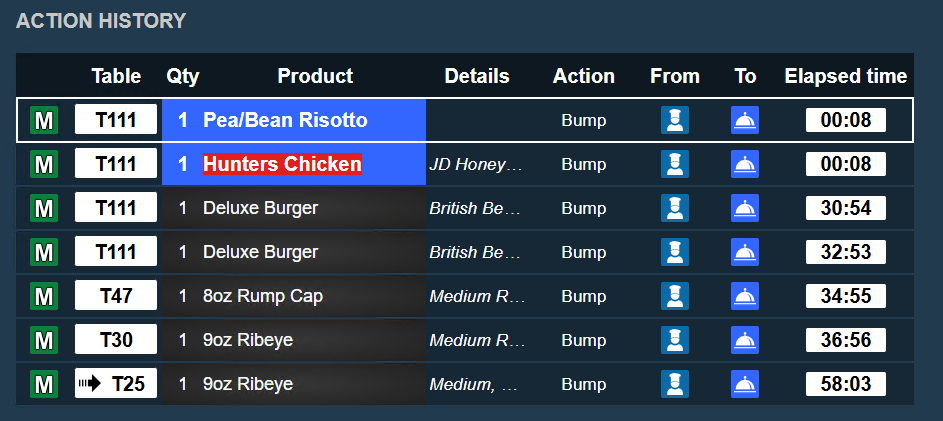

Onsite Operations - Action History

Screen Enhancements to Action History

The Action History screen has been enhanced to provide a clearer view of all actions performed on a channel.

Pressing and holding the Undo button will open the action history, displaying the most recent actions at the top.

When selecting an item, you can choose to 'Bump To' another station or 'Undo' to return it to the current station.

Configuration & Onsite Operations

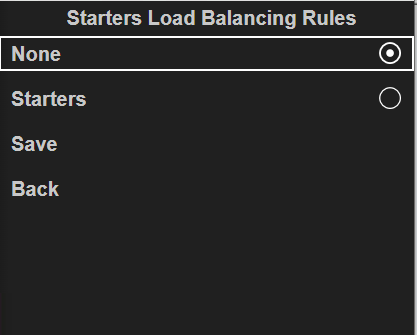

Order Load Balancing

To enhance onsite operations, a new configuration allows orders to be distributed across multiple stations. Customisable rules enable a primary station to assign orders to one or more secondary stations, ensuring a balanced workload, orders are distributed in a 'round robin' style.

When additional workload balancing is needed, onsite operators can enable this feature and disable it once normal operational capacity is restored.